DACC CarbonManufacturing Technology

Design and Interpretation

- HOME

- Manufacturing Technology

- Design and Interpretation

Design and Analysis and our Capability

Based on 25 years of experience in developing and mass production of carbon composites for aircraft, automobiles, and aerospace, DACC Carbon can develop all products including materials selection, product design, development testing, and operational testing through the analysis from customer requirements.

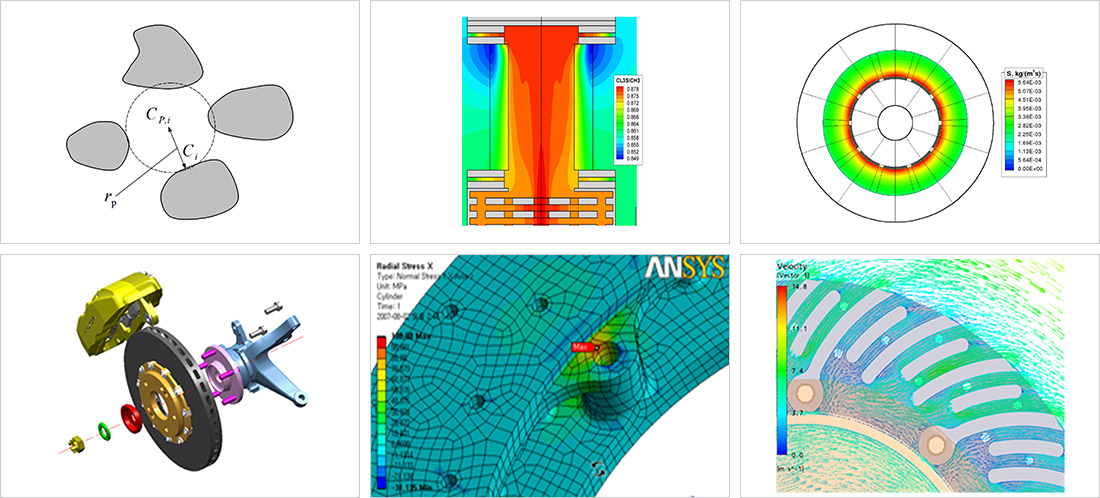

CVI(Chemical Vapor Infiltration) Process Modeling & Analysis

DACC Carbon develops and secures CVI process modeling and analysis technology, which is a key technology for manufacturing ultra-high temperature carbon composites through R&D cooperation with the industry, academia, and research institutions.

- - Composite design

- - Modeling process reactors and carbon fiber preform structures

- - Heat and mass transfer and flow analysis

- - Material reaction and thermodynamics analysis

Design & Analysis of Brake discs for Aircraft and Automobile

We have developed and secured technologies for designing and analyzing carbon composite brake discs, the key components of aircraft and automobile brake systems.

- - Design of composite structures and materials

- - Structural stability of brake discs through thermal and mechanical stress analysis

- - Brake disc cooling performance through heat and flow analysis

Design

3D CAD Modeling, optimal lightweight design, large composite structure design, fatigue/damage tolerance design, shock-resistant design, heat resistance/abrasive material design, friction material design, bulletproof structure design

Design and Analysis Software

CATIA, AutoCAD, CFD-ACE +